Description

LMS Ceiling Carrier Roll Forming Machine

Precision Engineered for Suspended Drop Ceiling Systems

Overview

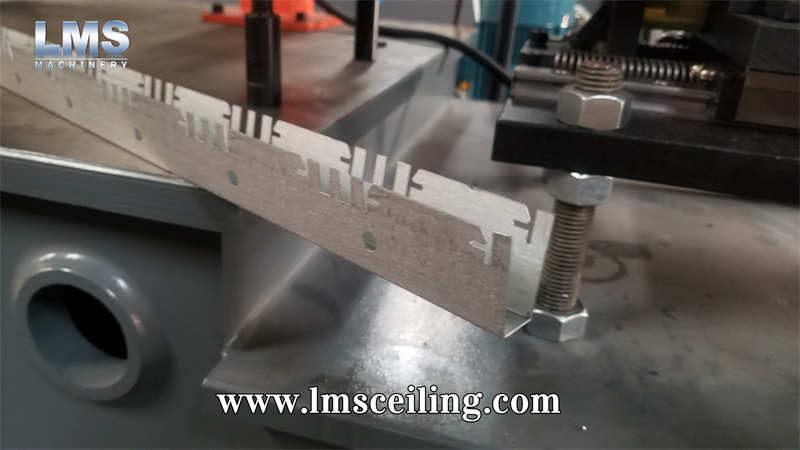

The LMS Ceiling Carrier Roll Forming Machine is an automated production solution designed for high-volume manufacturing of structural ceiling carriers – the critical backbone of modern suspended drop ceilings. Utilizing advanced roll forming technology, it transforms galvanized steel or aluminum coils into standardized LMS profiles (e.g., L24/L32/L48) with ±0.5mm tolerance, ensuring seamless integration with T-grids, panels, and MEP services.

🔧 Key Specifications

| Parameter | Capability |

|---|---|

| Material Thickness | 0.8-1.5mm (Galv. Steel / Aluminum) |

| Profile Width | 24mm, 32mm, 48mm (Customizable) |

| Production Speed | Up to 15m/min |

| Control System | PLC + HMI Touchscreen (Auto-Length Counting) |

| Power | 7.5kW (380V/50Hz or Customized) |

| Tooling Life | 500,000+ meters (Hardened CR12 Steel) |

🏆 Core Advantages

✅ Structural Integrity Optimization

-

Rolls cold-formed high-tensile steel (550MPa+) into uniform LMS carriers, achieving load capacities up to 1,200kg/m² (EN 13964 certified).

-

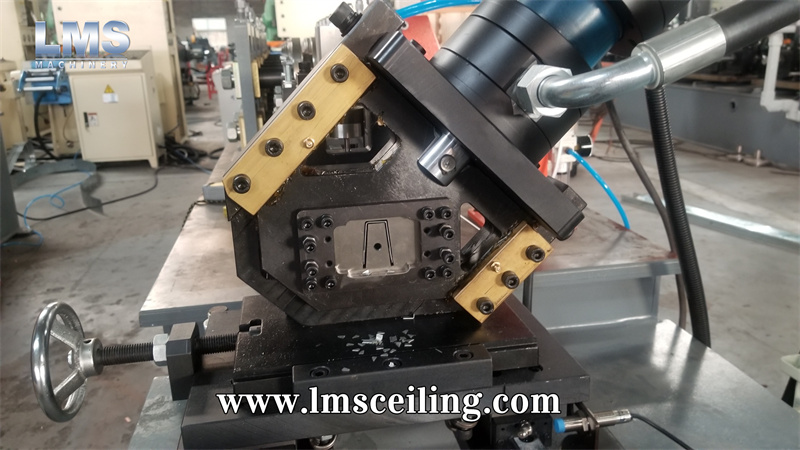

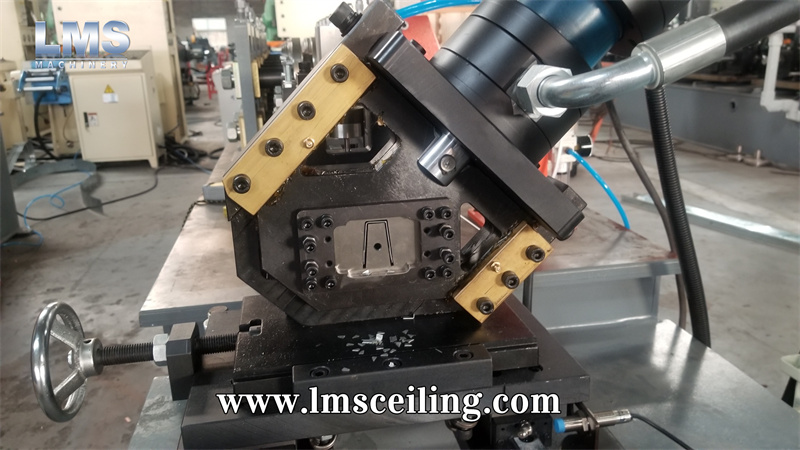

Precision notching/punching units create interlocking joints and service openings for HVAC/lighting, eliminating onsite cutting.

✅ Labor & Cost Efficiency

-

1-operator control reduces manpower by 70% vs. manual fabrication.

-

Integrated coil decoiler + servo-cutting minimizes material waste (<3%).

✅ Seismic & Fire Compliance

-

Profiles meet ASTM E580/E580M (seismic zones) and EN 13501-1 (fire resistance) requirements.

🏢 Application Scenarios

-

Commercial High-Rises: Rapid production of heavy-duty carriers for large-span ceilings (airports/malls).

-

Healthcare/Education: Fabrication of antimicrobial-coated carriers for cleanrooms & wet areas.

-

Retrofit Projects: On-site roll forming for renovation (machine deployable in confined spaces).

⚙️ Smart Manufacturing Features

| Module | Function |

|---|---|

| Auto-Thickness Detection | Adjusts roll pressure for material variance |

| Cloud Data Monitoring | Tracks OEE, downtime, and maintenance alerts |

| Quick-Change Tooling | <10 min profile switch (L24↔L48) |

🌍 Why Choose LMS Ceiling Carrier Machine?

“From coil to installed carrier in 3 steps – unmatched ROI for contractors and panel manufacturers.”

-

For Contractors: Cut installation time by 40% with pre-punched service holes.

-

For Material Suppliers: Offer value-added branded carriers (logo embossing available).

-

For Exporters: CE-certified with voltage adaptability (220V-480V).

Technical Support: Includes 3D simulation of profile designs + on-site training.

Contact us: For BIM/CAD files of standard LMS profiles and dust extraction solutions.

Reviews

There are no reviews yet.