Description

Classic Grilyato Open Cell Ceiling Making Machine

| Raw material | Gi steel, Aluminum |

| Product size | 10/15mm width, 30/40/50mm height |

| Open cell size | 75*75/100*100/150*150/200*200mm |

| Production capacity | 8-10m/min |

| Electricity requirement | 380V 50Hz 3 Phases |

| Power consumption | 10KW |

II. Process flow of LMS Classic Grilyato Cell Ceiling machine

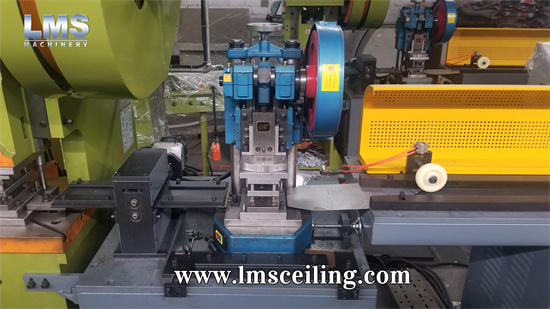

Hydraulic Decoiler — Precision Leveler — Perforation Press — Cut To Length Press Machine — Main Roll Forming Machine — Product Output Table

III. Key Features of Punch dies information

IV. LMS Open Cell Ceiling Machine Photos

lms grilyato open cell ceiling machine

V. Application Area:

Grilyato ceilings are widely suited for diverse public, commercial, and institutional spaces, including:

Transport hubs: Airports, railway stations, and bus terminals

Commercial & exhibition venues: Shopping centers, exhibition halls, and catering establishments

Hospitality & entertainment spaces: Hotels, concert halls, and cinemas

Institutional facilities: Medical institutions and educational institutions

Reviews

There are no reviews yet.