Description

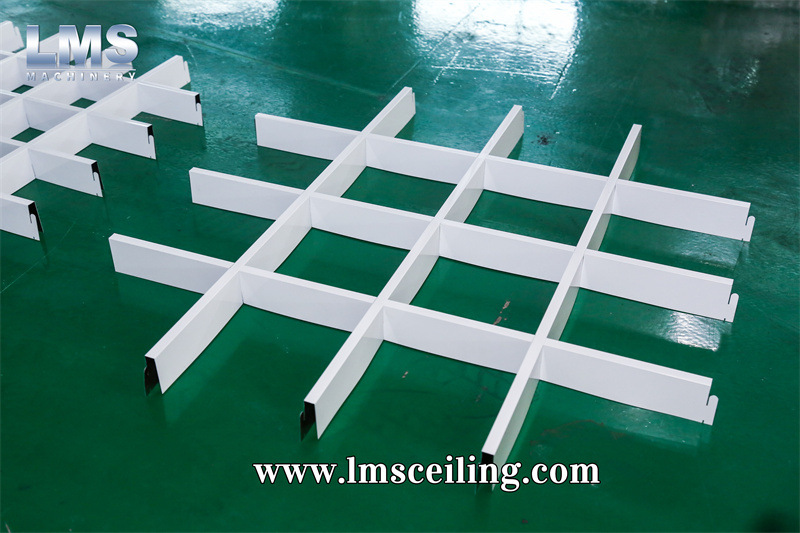

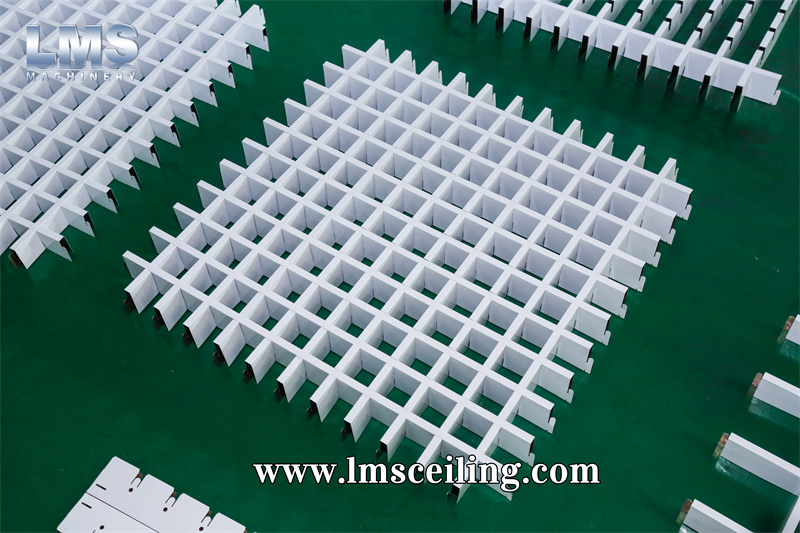

LMS High Speed Grilyato Ceiling U10x30-50 Production Line is mainly used for the high-speed production of U10 suspended open cell ceiling grilyato with the speed of 0 ~ 30 m/min. The full production line includes decoiler, leveler, hydraulic punching & cutting unit, conveyor, roll forming machine, run-out table and electric control system.

High Speed Grilyato Ceiling Roll Forming Machine Suitable Material Specification:

| NO. | Item | Specification |

| 1 | Material | Aluminum / Steel |

| 2 | Material Thickness | 0.25 ~ 0.35 MM |

| 3 | Profile Size | U10×27 / U10×40 MM (Top & Low Profiles) |

| 4 | Punching Step | 30 / 50 / 60 / 75 / 100 / 120 / 150 / 200 MM (8 Sizes) |

| 5 | Cutting Length | 605.5 / 1200 / 2400 MM |

| 6 | Production Speed | 0 ~ 30 M/Min (50 / 100 / 150 / 200 MM Gap) |

| 7 | Cutting Tolerance | ±0.1 |

High Speed Grilyato Ceiling Production Line Production Process:

Material Coil → Decoiling → Leveling → Hydraulic Punching & Cutting → Conveying → Roll Forming → Discharge → Finished Profile.

High Speed Open Cell Ceiling Grilyato Roll Forming Machine Composition Of Complete Production Line:

| NO. | Equipment | Qty. |

| 1 | Decoiler | 1 Set |

| 2 | Leveler | 1 Set |

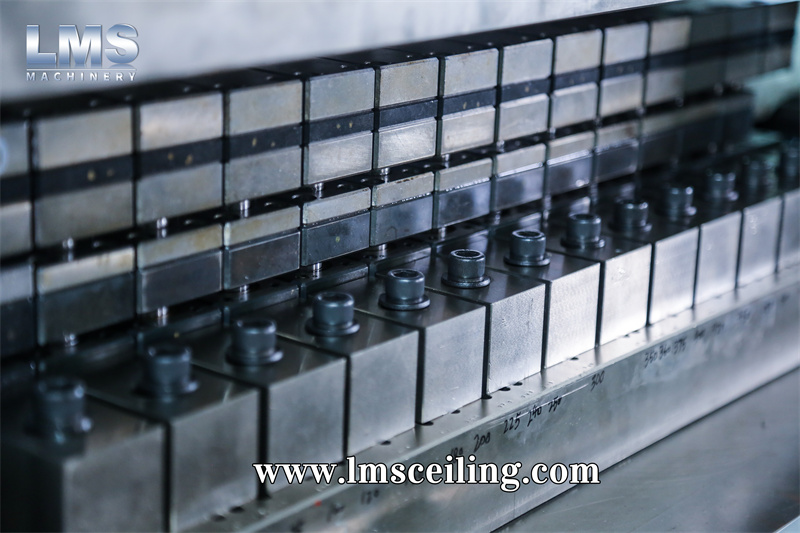

| 3 | Hydraulic Punching & Cutting Unit | 1 Unit |

| 4 | Conveyor | 1 Set |

| 5 | Roll Forming Machine | 1 Set |

| 6 | Run-Out Table | 1 Set |

| 7 | Electric Control System | 1 Unit |

Reviews

There are no reviews yet.