Description

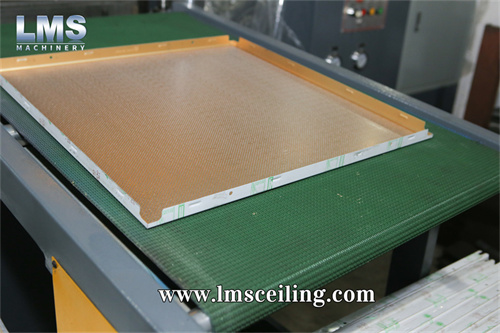

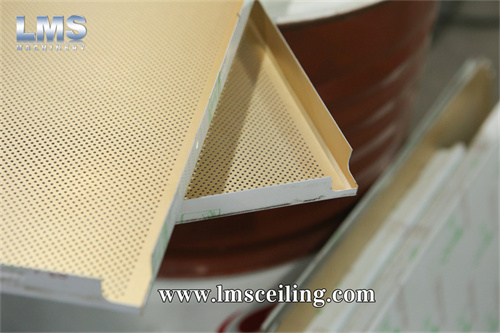

LMS Square Perforated Metal Ceiling Panel Production Line

600×600 Metal Ceiling Tile Production line Production Process:

Decoiling – Simple Film Applicator – 1# Leveling – Perforation (Yangli Press) – Corner Cut – Conveyor – 2# Leveling – Turnover Unit – Manipulator – Bending – Finished Tile.

Aluminum Ceiling Panel Roll Forming Machine Composition Of Complete Production Line:

| NO. | Equipment | Specification | Qty. |

| 1 | Hydraulic Decoiler | With Coil Car (Optional) | 1 Unit |

| 2 | 1# Leveler | Including Integrated Film Applicator | 1 Unit |

| 3 | Perforation (Power Press) | With Servo Feeder | 1 Unit |

| 4 | Corner Cut (Hydraulic Press) | 40T (600×600) / 80T (1200×600) (Optional) | 1 Unit |

| 5 | Conveyors | 1# – Between Cutting Unit And 2# Leveler.

2# – After Bending |

2 Units In Total |

| 6 | 2# Leveler | 21 Leveling Rolls | 1 Unit |

| 7 | Turnover Unit | Integrated In Conveyor | 1 Unit |

| 8 | Manipulator | Transfer Material After Turnover Into Bending Tool | 1 Unit |

| 9 | Bending Press | 120T For 600×600 Forming (Clip-In / Lay-In) (Optional) | 1 Unit |

| 10 | Control System | YASKAWA Servo Motor; PANASONIC PLC | 1 Unit |

| 11 | Tools (Customized) | Perforation, Corner Cutting And Bending Tools | 1 Set |

Photos of Every component of the metal ceiling machine:

1. Hydraulic Uncoiler

2. #1 Leveler

3. Perforation Punch press ( hole punch / perforation punch press) with NC feeder

change mold to make 1.8mm, 2.3mm, 2.5mm, 3.0mm holes

4. Corner cutting and cut-off oil press machine

5. Conveyors

6. #2 Precision Leveler of metal ceiling making machine

7. Turnover Unit

8. Manipulator

9. Bending press

RELEVANT PRODUCTS:

-

-LMS Drywall Partition Stud And Track Roll Forming Machine

-

-Ceiling U Baffle Roll Forming Machine

-

LMS Linear Strip Ceiling Roll Forming Machine

-

-Ceiling Light Steel Keel Machine ( Triangle Machine | T Grid Machine | Carrier Machine)

-

-LMS Open Cell Ceiling Grilyato Production Line

-

-Ceiling Furring Roll Forming Machine

Reviews

There are no reviews yet.